Do Gas Pipes Have to Be Copper? (TRUTH REVEALED!)

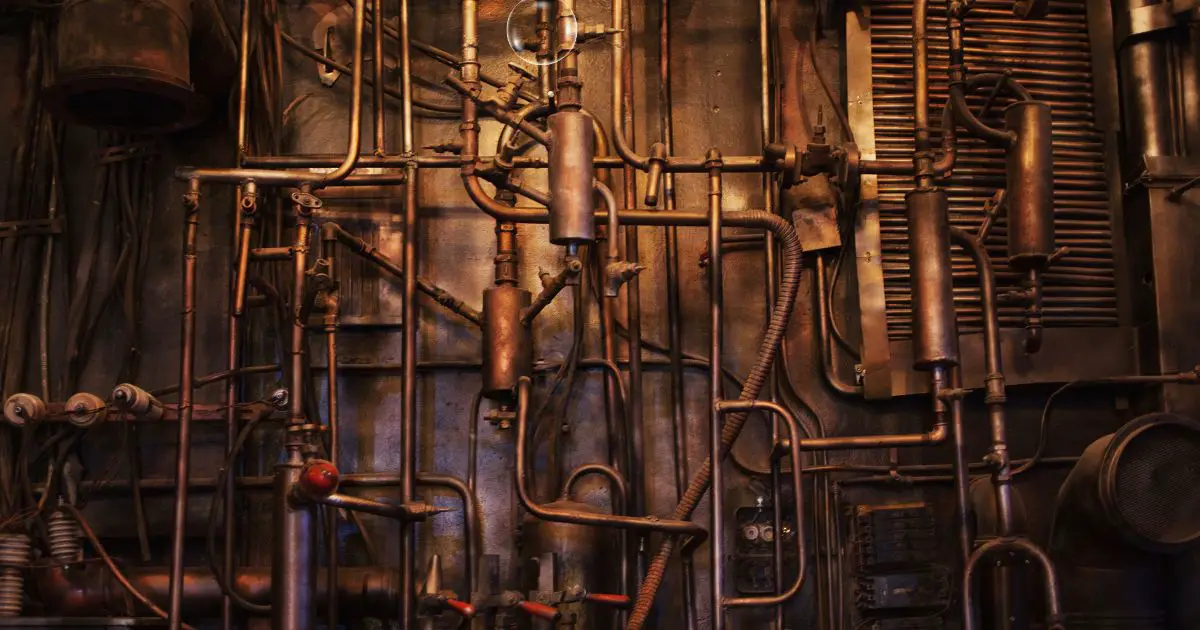

Gas pipes are a vital component of any modern home, providing the power to run appliances and keep your family comfortable.

Copper pipes have long been used for gas pipe installation due to their proven quality and reliability, but is copper really necessary?

In this article we’ll explore whether alternative materials can offer comparable safety and performance when it comes to gas pipe systems.

Do Gas Pipes Have to Be Copper?

Generally Speaking Yes, gas pipes must be made of copper. Copper is the most common material used for gas pipes due to its durability and resistance to corrosion. Copper is also non-combustible, making it a safe choice for gas pipes. Copper gas pipes are also easy to install and maintain, making them a popular choice for many homeowners.

Can you use copper for natural gas line?

Yes, copper is a great option for natural gas line given its proven track record as a durable material with excellent thermal conductivity.

Copper piping is strong and can withstand high pressures associated with the delivery of natural gas, making it one of the most popular choices for transporting this type of fuel.

The malleability of copper also makes it an ideal choice since it requires fewer fittings than other types of pipe material when running long distances.

Copper pipes need to be properly sealed in order to form an airtight seal that will prevent any leakage or infiltration of combustible gases into living spaces.

This often involves soldering joints together along the length of the pipe run using a special flux-cored solder designed specifically for use on metal gas lines.

It’s important to ensure that all connections are done properly in order to maintain safety standards and avoid potential hazards such as fires or explosions resulting from leaking natural gas fumes.

In addition, copper has good corrosion resistance compared to other materials like steel which means you won’t have to worry about having your pipeline replaced due to rust buildup over time.

Copper pipelines last much longer than plastic ones too which make them well worth their price tag if you’re looking for an effective and reliable way to transport your natural gas supply safely and efficiently throughout your home or business premises.

Why Copper is Used for Gas Pipes?

Copper is a preferred choice for gas pipes, due to its high durability and corrosion resistance.

As an alloy of zinc and tin, copper provides a strong enough material that can withstand the pressure generated by the gas running through the pipes.

Copper does not rust or corrode easily compared with other metals; this makes it ideal for being used in areas where moisture content is high.

Additionally, copper has excellent thermal conductivity which helps reduce heat loss when transferring natural gas from one location to another.

In addition to these qualities, copper also offers great flexibility when handling different piping configurations as well as ease of installation.

Finally, using copper pipes reduces noise levels associated with running natural gas lines because of its superior insulation properties and sound-deadening capabilities.

Alternatives to Copper for Gas Pipes:

When it comes to gas pipes, copper is the traditional choice.

But it’s not the only material available and there are alternatives that can be used instead.

Black steel pipe:

One popular alternative is black steel pipe.

Steel has been commonly used for decades in plumbing applications because of its strength, durability and low cost.

It also stands up well against temperature changes, which makes it suitable for a wide range of environments.

However, steel does require extra protection measures such as coatings or epoxy linings to prevent corrosion.

PVC or Polyvinyl Chloride piping:

Another option is PVC or Polyvinyl Chloride piping, which is lightweight and relatively easy to install compared with metal piping systems – making it an attractive choice for do-it-yourselfers who don’t have experience working with copper pipes.

PVC requires additional fittings but provides increased resistance against leaks from pressure fluctuations within a system as long as the proper connection techniques are utilized during installation.

PEX (Crosslinked Polyethylene):

Lastly, PEX (Crosslinked Polyethylene) tubing offers a flexible solution for tight spaces where copper might not fit easily—such as around corners or curves—or locations that experience frequent vibration when transporting natural gas through conventional rigid materials may cause failure due to fatigue over time.

Additionally PEX has heat resistance capabilities up to 200°F making it ideal in hot water applications like hydronic heating systems too!

Advantages and Disadvantages of Non-Copper Piping Options:

Non-copper piping options offer advantages and disadvantages when used in gas pipe applications.

Plastic pipes:

Plastic pipes are durable, flexible, lightweight and relatively inexpensive compared to copper.

They also have low thermal conductivity meaning they’re not as affected by temperature changes as copper is.

On the downside, plastic can be more difficult to install due to its flexibility and it does not provide corrosion protection like copper does.

Additionally, some plastics can become brittle over time making them less reliable for long term performance.

Steel pipes:

Steel pipes are strong and durable which makes them suitable for underground installations but steel will rust quickly if exposed to moisture or other corrosive elements so coatings or wrappings may be required in certain conditions.

Steel also has a greater potential of condensation buildup than copper which can create safety issues with gas lines that need careful monitoring during installation and operation.

Other non-copper materials such as stainless steel or brass may also be used for gas pipe applications but these can be expensive compared to plastic and steel alternatives while offering similar strengths and weaknesses respectively.

Why is copper not allowed for gas piping?

Copper is an excellent material for plumbing pipes; it is strong, durable and corrosion resistant.

However, copper cannot be used for gas piping because of its susceptibility to oxidation when exposed to certain gases.

This oxidation can lead to the weakening or degradation of the pipe walls over time, leading to potential leaks or even explosions.

In addition, copper has a relatively low melting point which can make it unsafe in high-temperature applications such as those associated with gas pipelines.

For these reasons, most local building codes require that gas systems use materials other than copper for their piping needs.

Steel is one commonly used alternative due to its greater strength compared to copper and much higher melting point.

Galvanized steel may also be used as it provides extra protection against corrosion from exposure to moisture in the environment or condensation from the system itself.

Other materials like polyethylene have become popular options due to their flexibility and low cost but should only be installed by experienced professionals who are knowledgeable about proper installation techniques for this type of pipe material.

International Safety Regulations on the Use of Different Types of Pipeline Materials:

Pipeline safety is an area of increasing importance, especially when it comes to installation and use.

When selecting the materials for a gas pipe, it’s important to understand the different international safety regulations that must be followed.

When it comes to pipeline materials, copper has been considered one of the most reliable options due to its durability and resistance against corrosion.

However, there are also other types of pipeline materials such as steel or plastic that can be used in certain applications.

Each type of material may have their own set of regulations which must be met in order for them to remain safe and effective.

International standards exist regarding the maximum temperatures at which each material is suitable for use with gas lines; these should always be taken into consideration when installing a new pipe system.

Additionally, any changes made during or after installation must meet safety requirements in order to avoid accidents or damage caused by incorrect setup procedures.

Regular maintenance should also be conducted on pipelines using any type of material in order ensure compliance with all applicable laws and regulations governing their proper usage.

Can you use plastic pipe for gas?

Yes, plastic pipe can be used for gas. Many plumbing systems now use polyethylene and other types of plastic tubing to transport natural gas or propane.

When properly installed, these pipes are both safe and durable.

Plastic pipes offer several advantages over copper when it comes to installation and maintenance.

They often require fewer fittings since the sections of pipe can be easily connected using special seals or glue, saving time during installation.

Additionally, they are non-corrosive and have a significantly longer lifespan than copper piping due to their durability against external factors like temperature changes or harsh chemicals.

When selecting a type of plastic pipe for transporting gas, it is important that you choose one approved by your local building department as well as the relevant safety codes in your area – such as those enforced by the National Fire Protection Association (NFPA).

The appropriate materials should also carry certifications from organizations such as Factory Mutual Research Corporation (FMRC) or Underwriters Laboratories (UL).

These will ensure that the piping meets necessary standards for home safety and efficiency.

Can I use galvanized pipe for gas?

Yes, you can use galvanized pipe for gas.

Galvanized steel is perfectly suitable for natural gas and propane applications, as long as it meets the necessary safety requirements.

All pipes used in a gas line must be approved by local building codes before installation to ensure that they are safe for use with combustible materials.

Galvanized pipe is often preferred over copper because it’s cheaper and easier to install.

It also has many other advantages such as resistance to corrosion, ease of maintenance and flexibility – galvanized pipes can bend around corners without needing additional supports or fittings.

However, while galvanized steel may be used in some cases when transporting natural gas or propane, copper remains the most common material of choice due its superior strength and durability compared to other non-ferrous metals like aluminum or plastic piping systems.

Copper piping also requires less energy than plastic alternatives due its higher thermal conductivity which helps reduce heat loss during transmission.

Additionally, copper won’t corrode over time like steel so there’s no need to regularly perform maintenance on the system once installed correctly; this makes it an ideal option for those who want a reliable long-term solution that requires little upkeep

Conclusion: Do Gas Pipes Have to Be Copper?

In conclusion, gas pipes do not have to be copper.

Many materials can be used for the installation of natural gas lines, depending on various factors such as cost, durability, and safety.

However, in some cases it may be necessary or preferable to use copper pipes due to its ability to resist corrosion and heat better than other materials like plastic and steel.

Additionally, copper is a naturally occurring material that does not need further processing before being installed in a home or business.

Although there are many valid reasons why someone would choose copper over other types of piping material for their gas line installation project, it is important to remember that safety should always be the primary consideration when deciding which type of pipe material is best suited for your needs.