Do You Need a Regulator on a Gas Line? (Answer Surprise You!)

A regulator on a gas line is an essential safety feature that ensures the safe and efficient use of your gas-powered appliances.

Not only does it help reduce the risk of fire or explosion from over-pressurization, but it also helps to ensure that you are getting the most out of your fuel by delivering its maximum potential power.

This article will discuss why regulators are necessary for any setup involving a gas line, as well as how to properly install one in order to get the best performance out of your system.

Do You Need a Regulator on a Gas Line?

Installing a gas line regulator is important to reduce pressure and maintain safe working conditions within your home or business. It is recommended that the pressure remain between 7-11″ water column (WC), as this will not exceed 1/2 pound per square inch (psi), allowing appliances to operate safely and efficiently.

What Is a Gas Line Regulator?

A gas line regulator is an essential piece of equipment that helps to control the pressure and flow rate of a natural gas system.

It ensures that the right amount of fuel is used for each application, reducing waste and optimizing energy efficiency.

The function of a regulator is to maintain constant inlet pressure while allowing the outlet pressure to vary according to demand.

Depending on what type of appliance or fixture you are connecting your gas line to, you may need one or more regulators installed along the length of your pipe.

For example, if you are installing a stovetop range, two regulators may be necessary: one near where it connects with your main line and another located close by for safety purposes.

Installing multiple regulators also prevents backflow from different appliances affecting each other’s performance.

When selecting a regulator for your particular needs, there are several factors which must be taken into consideration such as size, capacity and maximum operating temperature rating (MOTR).

In addition, it’s important to ensure that all parts meet relevant safety standards so as not to compromise user safety when using natural gas lines within any domestic environment.

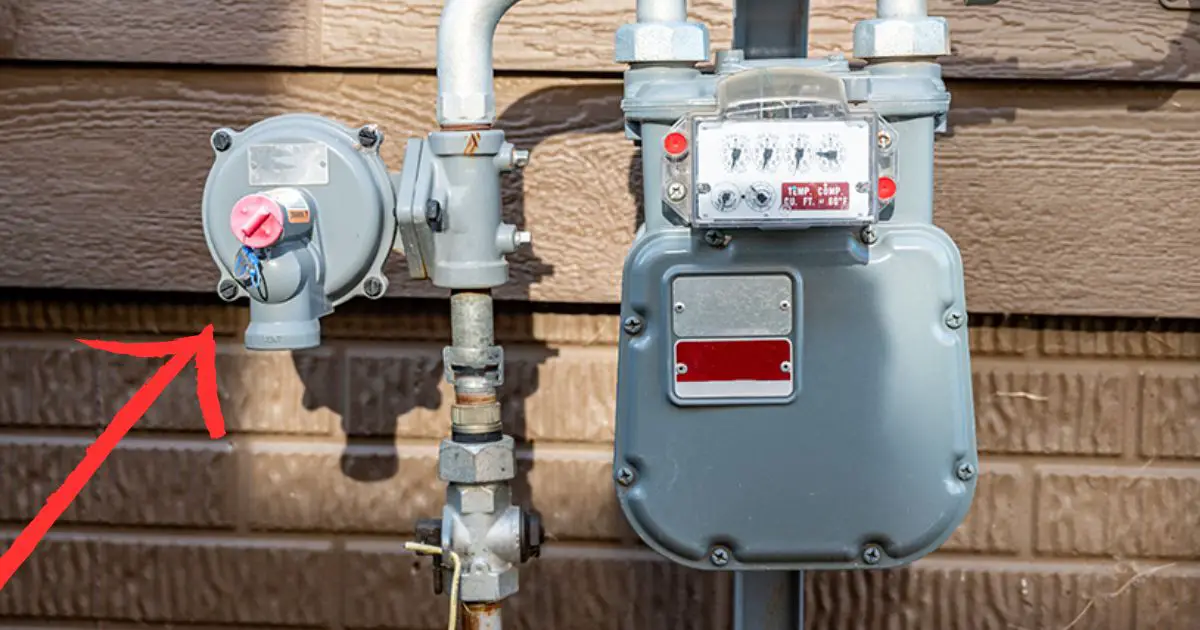

Where should a gas regulator be installed?

When installing a gas regulator, it is important to ensure that the device is placed in an area that meets safety requirements.

The ideal location for a gas regulator installation is typically outdoors or near an outside wall, where there are no combustible materials nearby and plenty of ventilation to disperse any fumes created by the operation of the device.

Furthermore, regulators should not be installed in areas prone to flooding or excessive moisture as this could damage the components over time.

In addition, proper clearance should always be maintained when installing a gas regulator – at least 30 cm from any flammable material and 10 cm above grade – so as not to create a fire hazard in case of accidental ignition.

Similarly, if multiple regulators are used on one line they must be properly spaced out with enough space between them for both maintenance access and safe operation.

Before beginning any installation process it’s vital that all relevant building codes regarding gas lines have been adhered too; failure to do so can put lives at risk due to potentially unsafe conditions caused by improper installations.

What is the difference between a gas valve and regulator?

A gas valve and regulator are two different types of components in a natural gas line.

Both are used to control the flow of natural gas from one point to another, but they have different functions and use different technologies.

A gas valve is responsible for turning the flow on and off. It uses a mechanical lever or switch that can open or close the pipe to allow more or less gases through.

The amount of pressure in the line remains constant; it is not adjusted by this type of component.

A regulator, on the other hand, adjusts both the amount of pressure and flow rate in a pipeline as needed for specific tasks such as heating water or cooking food.

It typically contains an internal diaphragm which compresses when exposed to increased pressure, allowing controllers to adjust it up or down at will without having direct contact with any volatile components.

This makes them extremely safe while also being highly efficient methods of controlling the movement and delivery of natural gases through pipes safely over long distances with minimal risk of explosion due to excess pressures reaching release valves downstream.

Different Types of Gas Line Regulators:

When it comes to gas lines, regulators are essential pieces of equipment.

They help control the pressure and flow of gases like propane, natural gas, and methane.

Without a regulator in place, you could have dangerous fluctuations in the pressure or rate of flow that can lead to explosions or other serious injuries.

There are several different types of gas line regulators available depending on your needs.

Adjustable regulator:

The most common type is an adjustable regulator which is designed to allow for manual adjustments according to changing conditions such as temperature and altitude changes.

Diaphragm regulator:

Another type is a diaphragm regulator which uses flexible membranes to regulate pressure by opening or closing valves at certain pressures.

Spring-loaded regulators:

Finally, there are spring-loaded regulators which work similarly but use springs instead of membranes for more precise regulation levels over time.

No matter what kind of system you have set up with your gas line, having a quality regulator installed correctly is paramount for safety reasons as well as efficiency purposes.

Doing some research before you buy will ensure that you get the right model for your specific application so that all goes smoothly without any mishaps down the road!

How to Install a Gas Line Regulator?

Installing a regulator on a gas line is an important step to ensure the safe and efficient operation of your gas appliance.

A regulator helps maintain consistent gas pressure, preventing surges or fluctuations in flow rate that can damage equipment.

It also ensures that any combustible gases are contained within the pipe.

When installing a regulator, it’s important to follow local codes and safety regulations. The size of the regulator should match the size of the pipe – larger pipes require larger regulators; smaller pipes require smaller ones.

Make sure you use appropriate piping material such as galvanized steel or stainless steel as these materials are resistant to corrosion and temperature changes caused by fuel combustion.

Additionally, all connections must be securely tightened with wrenches or pliers and sealed with thread tape before being tested for leaks using soap bubbles or electronic leak detectors.

Once installed, regularly inspect your gas line system for signs of wear-and-tear such as loose fittings; cracked seals; rusting components; clogged filters; etc.,

These issues can cause unsafe performance levels so act quickly if either is detected!

Lastly, always make sure you’re aware of emergency shutoff valves located near each appliance so they may be closed off in case of an emergency situation occurs

Benefits of Installing a Gas Line Regulator:

1. Improved safety:

Gas line regulators help to regulate the flow of gas which reduces the risk of fire or other hazards associated with unregulated gas lines.

2. Enhanced energy efficiency:

Installing a gas line regulator can help reduce energy costs by minimizing the amount of gas that is lost through leakages in the system.

3. Better system control:

Gas line regulators help to control the pressure and flow rate of the system, allowing for smoother operation and more precise control.

4. Reduced maintenance costs:

Gas line regulators reduce wear and tear on components, helping to extend their lifespan and reducing maintenance-related costs over time.

5. Increased system performance:

By regulating the flow rate and pressure of a gas line system, a regulator helps improve overall performance and operation while reducing the risk of complications or malfunctions.

Potential Problems with Not Having a Regulator on the Gas Line:

When dealing with gas lines, having a regulator is essential for safety. Without a regulator, the flow of gas can be too high or too low and increase the risk of dangerous explosions.

Additionally, not having a properly calibrated regulator could cause an insufficient supply of fuel to appliances that require it.

This could lead to poor performance and even damage to equipment due to inadequate heating or cooling caused by improper pressure regulation.

In addition, without a gas line regulator in place, backdrafting may occur into the home from combustion exhausts like furnaces or hot water heaters which can introduce deadly carbon monoxide gas into living spaces.

Fumes are especially likely if there is no ventilation system present in the area where these appliances are installed.

Finally, not using a proper regulator on your gas line increases wear and tear on any connected appliances since they won’t receive consistent fuel delivery when under varying pressures created by an unregulated line.

Without regular maintenance checks for potential problems with the appliance’s operation due to incorrect pressure adjustments this can create major issues down the road including irreparable damage and reduced longevity of any connected devices that rely upon regulated fuel delivery from your gas line.

Cost Considerations for Installing or Replacing an Existing Regulator:

Cost considerations for installing or replacing an existing regulator are important to consider when determining whether one is necessary on a gas line.

The cost of the regulator and installation will vary depending on factors such as type, size and complexity of the system.

Generally, regulators range in price from $50-$500+.

Installation costs can be anywhere from a few hundred dollars up to several thousand dollars depending on access issues and difficulty with placement.

In addition, if you’re considering replacing an old regulator or upgrading it due to age or increased demand, there may be additional labor and material costs associated with removing the component that needs replacement.

Additionally, any safety valves installed downstream of the regulator must also be inspected before changing out components to ensure they are still functional.

The nature of work required by professional installers must also be taken into consideration when budgeting for regulation installation or replacement.

This could include running new piping through walls or floors as well as connecting elements together in confined spaces – all which require time-consuming expertise which could add expenses onto your project.

Conclusion:

Regulators ensure that the gas line is not damaged by excessive pressure.

If there is no regulator installed on your gas line, you could experience leaks or bursts of flame due to increased pressure.

By investing in a regulator for your gas line, you can safeguard against any potential issues.