Is Black Gas Pipe Steel or Iron? (SECRET REVEALED!)

When it comes to the choice of material for gas pipe installation, many people are unsure whether to choose steel or iron.

While conventional wisdom might dictate one over the other, there is a hidden gem that lies beneath: black gas piping.

This type of piping has its own unique benefits when compared with traditional materials and could be just what your next project requires.

Read on to discover more about this reliable and efficient option!

Is Black Gas Pipe Steel or Iron?

Black gas pipe is made of steel, not iron. Steel is a strong and durable material that is resistant to corrosion and rust. It is also more cost-effective than iron, making it a popular choice for gas pipes. Steel gas pipes are also easier to install than iron pipes, making them a great choice for DIY projects. Steel gas pipes are also more resistant to temperature changes, making them a great choice for outdoor applications.

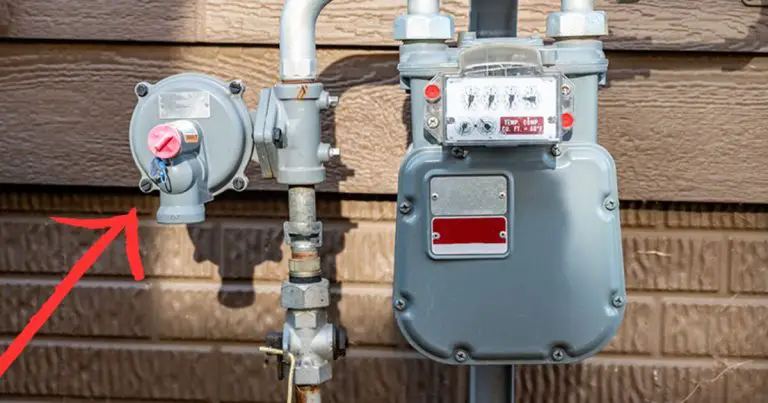

What is black gas pipe?

Black gas pipe is commonly utilized in residential and commercial settings alike, where it provides a quiet, yet effective atmosphere.

This alloy of steel possesses excellent resistance to corrosion, making it ideal for use in piping systems; however its colouration may pose an issue.

Unfortunate instances can arise when homeowners mistakenly assume that the black color characteristic of steel piping is indicative of its composition.

This can result in unforeseen leakage or even structural damage if not remedied swiftly!

Should you discover any black mold growing on your pipes, don’t be alarmed.

It’s possible that they are merely remnants of old paint – simply remove it before proceeding with any repairs!

Is Black Gas Pipe Steel or Iron?

Black gas pipe is constructed from a combination of stainless steel and cast iron, providing extra strength in addition to corrosion resistance.

If you’re planning to use this type of piping, it’s prudent to consider which material will be used; while cast iron can provide considerable protection against rust, its density renders it impractical when constructing large-scale installations such as apartment buildings.

On the other hand, the material chosen for steel pipes must be carefully scrutinized before deciding on your pick.

Due to the potential dangers associated with using lead-free solder, alloy steel piping is highly recommended.

This type of metal boasts superior strength without sacrificing any of its natural coloration!

Does black gas pipe rust?

Neglecting the exterior portion of your piping system can lead to leaks and all-round neglect that could potentially result in a major plumbing disaster.

However, black gas pipe will not rust if properly maintained; it is only exposed to oxygen during its production process.

Since their introduction, stainless steel pipe has been one of the most popular materials for natural gas piping installations – due largely to its durability, resistance to corrosion and ease of installation.

Fortunately, this type of metal boasts spectacular resistance against weathering when compared with standard pipes; even without any protective coating or surface treatment applied!

Ultimately resulting in a sleek finish that resists tarnishing and patina over time.

Types of Metal Used in Gas Piping:

Gas piping is a crucial component of any home that uses natural gas for appliances and heating.

It must be installed with materials that are safe, durable, and corrosion-resistant. Steel, copper, and aluminum are the three primary types of metal used in gas piping.

Steel is the most commonly used material, as it is cost-effective and durable.

Copper is also used for gas piping because it is resistant to corrosion and can handle high temperatures.

Aluminum also has a high resistance to corrosion and is lightweight, which makes it easier to install than steel or copper.

However, it can be more expensive than other metals, so it is often only used for short runs of piping.

No matter which type of metal is used in gas piping, it is important to ensure the material meets local building codes and safety requirements.

Advantages and Disadvantages of Steel vs Iron Gas Pipes:

Advantages of Steel Gas Pipes:

1: High Durability:

Steel gas pipes are extremely durable and can last for many years.

2: Corrosion Resistance:

Steel gas pipes are resistant to corrosion, which makes them ideal for outdoor use.

3: Low Cost:

Steel gas pipes are relatively inexpensive compared to other types of piping materials.

4: Easy Installation:

Steel gas pipes are easy to install due to their lightweight and flexible nature.

5: Fire Resistant:

Steel gas pipes are fire resistant and can withstand high temperatures, making them a safe option for homes and businesses.

Disadvantages of Steel Gas Pipes:

1: Corrosion:

Steel pipes are prone to corrosion due to their exposure to moisture and oxygen in the air.

2: Expansion and Contraction:

Steel pipes can expand and contract due to temperature changes, which can cause joints to become loose or even leak.

3: Cost:

Steel gas pipes are more expensive than other forms of gas pipe material such as plastic or copper.

4: Installation Difficulties:

Installing steel gas pipes can be difficult and requires professional help.

5: Maintenance Requirements:

Steel gas pipes require regular maintenance to prevent corrosion and leakage.

Advantages of Iron Gas Pipes:

1: Durability

– Iron gas pipes are extremely durable and can last for many years without needing replacement.

2: Cost-Effective

– Iron gas pipes are more cost-effective than other materials, making them a great choice for home and business owners.

3: Reliability

– Iron gas pipes are incredibly reliable, so you can trust them to deliver consistent results.

4: Low Maintenance

– Iron gas pipes require little to no maintenance, making them an ideal choice for those who want to save time and money on upkeep.

5: Safety

– Iron gas pipes are safe to use and have been tested to ensure they meet all relevant safety standards.

Disadvantages of Iron Gas Pipes:

1: Rust and Corrosion:

Iron gas pipes are susceptible to rust and corrosion due to their exposed nature in the environment. As a result, they require more frequent maintenance and can lead to leaks if left unchecked.

2: Prone to Damage:

Iron gas pipes are brittle and can easily be damaged by environmental factors, such as extreme temperatures or sudden impacts. This makes them prone to accidental damage or even vandalism.

3: Costly Installation:

Installing iron gas pipes is more expensive than other materials, due to the need for special tools and expertise. This makes them an impractical choice for many homeowners who are looking for a cost-effective solution.

4: Limited Lifespan:

Iron gas pipes have a limited lifespan compared to other materials, with an average of around 20-25 years.

Cost Comparison between Steel and Iron Gas Pipes:

When it comes to gas piping, steel and iron are two common materials used for the job.

Both of these materials are strong and long-lasting, but there are some key differences between them that can impact your decision when it comes to selecting a material for your gas piping project.

One of the main differences between steel and iron gas pipes is cost. Steel gas pipes are usually more expensive than iron gas pipes, with prices ranging from $2 to $5 per foot.

Iron gas pipes, on the other hand, are typically less expensive, with prices ranging from $0.50 to $2 per foot.

However, it is important to consider not just the upfront cost but also the cost of installation when making your decision.

Steel pipes tend to be easier and faster to install than iron pipes, potentially resulting in lower installation costs.

Additionally, steel is generally more resistant to corrosion than iron and therefore may have lower costs for maintenance over time.

Ultimately, it is important to weigh the pros and cons of each option in order to make the best choice for your project.

Which pipe is Best for a Gas Line Installation?

When it comes to gas line installation, you want to make sure you’re using the right type of pipe for the job.

The most common piping material for gas lines is steel, but there are other options available.

Depending on your needs, you may also choose copper, PVC, polyethylene, or even flexible corrugated stainless steel tubing (CSST).

Steel pipes are cost-effective and widely available, and are generally used for longer runs in residential areas.

Copper piping is often used in commercial gas line installations, due to its longevity and resistance to corrosion.

PVC is a popular option for residential interior gas lines, due to its affordability and ease of installation.

Polyethylene is often used for underground gas lines due to its durability and resistance to corrosion.

Finally, flexible CSST is frequently used in residential gas line installations due to its flexibility and ease of installation.

Ultimately, the best type of pipe for a gas line installation will depend on your individual needs. Be sure to consult a qualified installer before making any decisions.

Conclusion:

In the eyes of law, there is no distinction between black gas pipe steel and iron; both are regarded as cast iron products and fall within the scope of the product liability laws.

As for an individual purchase, it is advisable to consult with a plumbing contractor or architect before selecting materials for a project.

They may also provide valuable insight into whether or not using iron or steel pipes will yield optimal results.