Is It Ok to Use Teflon Tape on Gas Fittings? (Revealed)

When it comes to gas fittings, there are a few crucial steps you should take to ensure proper installation.

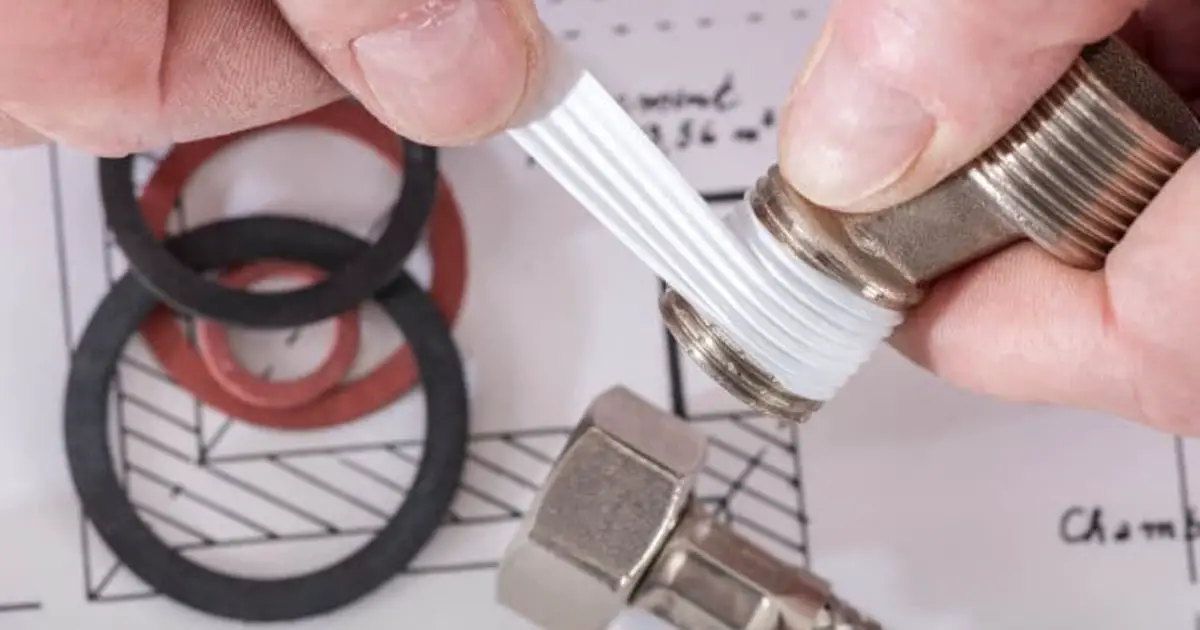

One of these is using Teflon tape for a secure and leak-proof seal.

Learn about the benefits of applying this tape to your gas fittings and how to do it correctly for optimal results.

Is It Ok to Use Teflon Tape on Gas Fittings?

Gererally Speaking Yes, it is OK to use Teflon tape on gas fittings. The tape should be wrapped three times around the fitting and tightened by hand, but not over-tightened. This will allow for a seal that is rated up to 3000 psi and temperatures up to 400°F (204°C). Additionally, the tape can provide protection against corrosion and helps stop small leaks from forming due to vibration or temperature changes.

What is Teflon Tape and How Does it Work on Gas Fittings?

Teflon tape is a convenient ad hoc solution that can be utilized to seal leaks and obstructions on gas pipes.

This versatile product comes in a range of thicknesses, making it possible to select the one that best suits your needs.

For such a versatile substance, Teflon tape has enjoyed widespread use in both industry and home applications alike: from sealing up small tears in clothing or fixing zips to sealing HVAC ducts in attics to preventing noise from escaping.

In addition, this material has also proven itself useful for patching broken seals on propane tanks and other similar installations – all at an economical cost!

How to Apply Teflon Tape to a Gas Fitting:

The application process for Teflon tape is simple and easy. First, identify the fitting you wish to seal.

Second, wrap the tape around the fitting three times.

Third, use your hands to firmly press down on the edges of the tape to create a secure seal.

Finally, allow the tape to cool before removing it.

There are a few things to remember when applying Teflon tape:

-Always use caution when handling high-pressure gas fittings.

-Make sure to reapply the tape if it begins to come off or peel away.

-Do not use Teflon tape on carbon steel gas fittings.

Is It Ok to Use Teflon Tape on Gas Fittings?

Yes, it is okay to use Teflon tape on gas fittings.

This type of sealant has become a go-to solution for the majority of DIY projects involving pipes and tube joints in the home.

It is specifically designed to create an airtight seal when applied correctly.

In terms of gas fitting applications, Teflon tape provides a strong barrier that won’t corrode over time, making it especially suitable for areas where temperatures and pressures can fluctuate quickly.

For added security, thread compound or pipe joint compound may be used in combination with the tape to provide extra protection against leaks.

Teflon tape also makes installation easier due to its malleable nature; this allows it to conform even more tightly around threaded connections than other options like putty or jointing compounds.

When applying tape around gas fittings you’ll want to ensure that each wrap is at least three times as wide as the threaded connection itself – any less will result in gaps where gases can escape from your system and cause potential harm if not dealt with properly by trained personnel before use.

Overall, using Teflon tape on gas fittings offers homeowners a reliable solution for sealing materials together securely while also providing flexibility during assembly and installation processes as required – so long as safety protocols are followed diligently throughout every step of application (i.e., turning off all power sources).

What Are the Different Types of Teflon Tape and Which is Best for Gas Fittings?

There are some prominent varieties of Teflon tape:

-Gel-Teflon Tape:

This type of tape is made from a blend of Teflon and fluorocarbon. The gel helps to create a tough, yet flexible seal, while the fluorocarbon creates a non-stick surface.

-PTFE Tape:

PTFE tape is highly resistant to oils and chemicals, making it ideal for use in high-pressure applications. It also has a low coefficient of friction, meaning it will grip materials tightly without causing wear or tear.

-N/A:

There is no specific type of Teflon tape designed for gas fittings – you’re free to choose whichever brand you prefer.

How to Properly Apply Teflon Tape to Gas Fittings?

When it comes time to apply the Teflon tape, there are a few methods that you can employ.

Regardless of the strategy chosen; however – all procedures must be carried out with caution lest accidents occur!

Set aside one end of the roll as a reference point, then unroll it evenly over both surfaces until fully adhered.

After that, use pliers or tweezers to remove any excess and ensure adequate coverage along every nook and cranny.

Cut off any excess with a sharp blade, then apply it in overlapping strokes in zigzag patterns.

This is an effective method for ensuring full coverage along the length of each piece of pipe.

Step by step:

1: Clean the threads of the gas fitting with a rag.

2: Wrap the Teflon tape around the treads in clockwise direction.

3: Make sure that the last layer of tape is overlapping with the first layer.

4: Ensure that the tape is tightly wrapped.

5: Trim any excess tape with a knife or scissors.

6: Tighten the fitting with a wrench to seal it properly.

Benefits of Using Teflon Tape for Gas Fittings:

1: Provides a tight seal that prevents gas leaks.

2: Does not corrode or degrade over time.

3: Creates an airtight seal on any type of gas fitting.

4: Easy to install and requires minimal preparation.

5: Resistant to high temperatures and chemical exposure.

6: Long-lasting and durable, providing a permanent solution for gas fittings.

Drawbacks of Using Teflon Tape for Gas Fittings

1: Teflon tape can become brittle and break over time, which can lead to leaks.

2: Teflon tape is not designed to be used with gas fittings, so it may not create a proper seal.

3: Teflon tape can be difficult to remove if it is applied incorrectly, leading to further issues with gas fittings.

4: Over-tightening of the threads when using Teflon tape can cause damage and leaks.

5: If the temperature of the connection exceeds 500 degrees Fahrenheit, the Teflon tape could potentially catch fire.

6: If the Teflon tape is not applied correctly, it can become dislodged from the fitting and cause a leak.

Teflon Tape vs. Other Materials for Gas Fittings

Teflon tape is an effective sealant for gas fittings, providing an additional layer of protection that can withstand temperatures up to 450°F/232°C.

This makes it an ideal choice for use in HVAC systems, where temperatures can fluctuate widely; however, depending on your individual preferences it may not be ideal for all applications.

Rubber and silicone caulk are the most common choices when it comes time to close up a leaky faucet.

In fact, this type of sealant is probably all you’ll have unless you’re specifically aiming for gas-fitting compatibility.

These materials are both easy to apply, but they also have a high coefficient of friction, meaning they can wear down quickly over time.

Silicone caulk is especially prone to leaking, though this can be remedied by using a silicone caulking gun that applies a thin bead of sealant at a time.

Safety Precautions When Using Teflon Tape with Gas Fittings:

Safety first:

1: Wear proper safety gear such as gloves, goggles, and a face mask.

2: Inspect fittings for any damage or cracks before use.

3: Clean the area around the fitting with a cleaning solution and a brush before applying the Teflon tape.

4: Apply the tape in a spiral motion along the fitting threads in the direction of screwing.

5: Wrap only three to four turns of tape around the fitting as too much can cause a leak.

6: Avoid over-tightening fittings as this may cause a leak or damage to the fitting.

7: Check for leaks after tightening by using soapy water around the fitting.

Conclusion:

The pros of using Teflon tape on gas fittings are that it provides a protective layer against corrosion, prevents leaks and reduces the risk of scalds and fires caused by gas leaks.

Teflon is a highly effective material that can significantly reduce the risk of gas-related incidents in your home or business.

However, while it is effective at preventing leaks and reducing potential hazards associated with this type of installation – it must not be used as an alternative to properly fitting and installing gas equipment.